Metallographic sectioning machines

For every cutting requirement

SM850 Metallographic Sectioning Machine

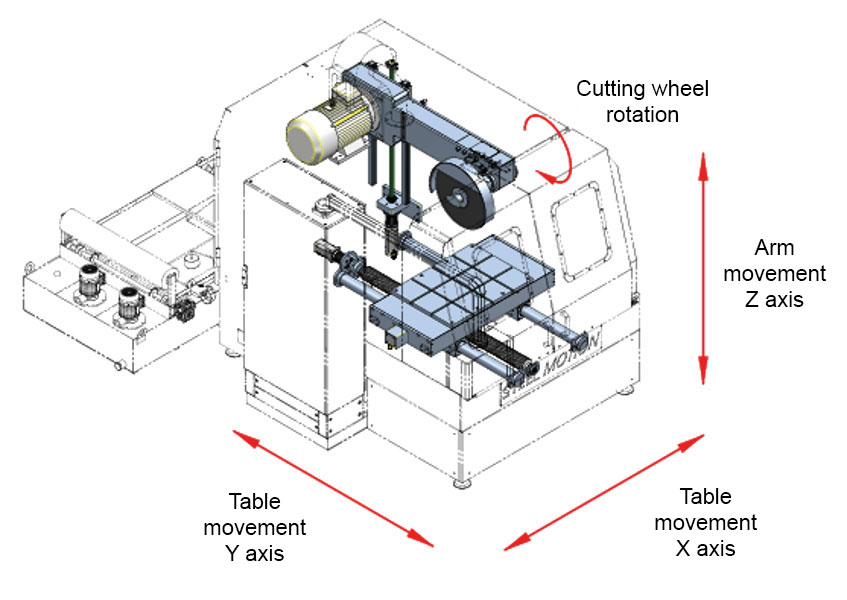

The SM 850 Sectioning Machine can accommodate cutting wheels up to 500 mm in diameter. It is designed to be extremely robust and versatile, meeting all cutting requirements.

The integration of advanced technologies and high-quality materials ensures a highly efficient, user-friendly, and precise instrument that delivers cuts without microstructural alterations.

The front cover features two transparent viewing windows that provide an extended view of the cutting area, further enhanced by a lighting system. The cutting area, exceptional for its category, measures 1200×1500 mm with a height of 1200 mm.

The color Touch Screen control panel allows for the storage of multiple cutting stages and work cycles. It also enables quick activation of the extraction system and the emulsifier filter.

Through the touch screen, it is possible to set:

- the travel of the axes,

- the cutting force limit, where the axis stops to relieve stress and then resumes,

- the rotation speed of the cutting wheel,

- the parameters for performing pulsed cutting. The program is extremely straightforward and intuitive, allowing easy access to all setting options.

Four nozzles are positioned around the cutting wheel to cool both the wheel and the workpiece during the sectioning phase, by spraying coolant fluid.

ELECTRICAL PANEL

It is built with a sturdy frame and has the following dimensions: 800 x 1600 x 400 mm (W x H x D). The components used are from Moeller, Siemens, Phoenix, and Finder. In addition to the electromechanical components managing the sectioning machine’s accessories, the panel also houses the axis drives and the inverter for the cutting wheel.

TOUCH SCREEN CONTROL PANEL

Model Elco Top 10, 10” color monitor. The panel includes both the human-machine interface and the integrated PLC. The PLC controls the sectioning machine’s accessories and the movement of the axes, which are driven by brushless motors with absolute encoders.

Included accessories:

EXTRACTION SYSTEM

An extraction system is essential to improve workplace air quality and to prevent condensation on the machine cover during cutting operations.

EMULSION FILTRATION

The fluid recycling system, equipped with a pump and sedimentation tank with a paper filter, is located near the sectioning machine. This system ensures a continuous supply of clean coolant during cutting operations, helping to cool both the workpiece and the grinding wheel.

Technical data:

| Description | Speed | Travel | Motor Power | Motor RPM |

|---|---|---|---|---|

| Axis X – Table | 0/1.5 m/min | 420 mm | 0.40KW | 3000 rpm |

| Axis Y – Table | 0/3.0 m/min | 1000 mm | 0.75KW | 3000 rpm |

| Axis Z – Arm | 0/1.5 m/min | 550 mm | 1.20KW | 3000 rpm |

| Cutting Wheel (max 500 mm) | 0/50 m/sec | 22.0KW | 1500 rpm | |

| Fume Extractor | 0.37KW | |||

| Washing Pump | 0.75KW | |||

| Coolant Pump | 0.75KW | |||

| Coolant Filter Motor | 0.12KW | |||

| PLC/Panel – Elco Top 10 | ||||

Steel Motion SRL a Socio Unico

Via della Tecnica, 265 • 41058 Vignola (MO)

+39 059 7122025 • steelmotion@steelmotion.it